NAVIGATION

Over the years, the company has always insisted on survival by quality, development by science and technology, based on the participation of all employees, and demanded benefits from management, dedicated to providing users with high-quality products and satisfactory services. The company continuously strengthens the quality assurance system which is led by the general manager of the company, presided over by quality assurance engineers, and operated cooperatively by the division of labor between the personnel of each quality control responsibility system, and has established and improved the quality management system and responsibility system. Our company passed the ISO9000 quality management system certification in 1998, and now has the design and manufacturing qualifications of Class III pressure vessels and the ASME "U" steel seal qualification. The company's pressure vessel quality management implements refined PDCA management system. According to the manufacturing characteristics of pressure vessels, combined with the actual situation of the company, it is divided into three stages: technical preparation, manufacturing, and final inspection, and include 9 control systems including design, materials (parts), technology, welding, heat treatment, inspection and testing, non-destructive testing, physical and chemical inspection, equipment and inspection, and test device, as well as 50 control links and 115 control points, of which 8 control points are stop points.

The company has Swiss Thermo Fisherm spectrometer, German Zeiss metallurgical microscope, universal testing machine, low temperature impact test device,TOFD+ phased array and other non-destructive testing equipment. The test equipment is advanced and complete, which can fully meet the requirements of chemical composition of pressure vessel, mechanical properties test, low temperature impact test, hardness test, intergranular corrosion test, RT, UT, MT, PT test of welds and materials and analysis of austenite and ferrite content of container manufacturing materials etc.

-

Metallographic analysis

-

Design Institute

-

Direct Reading Spectrometer

-

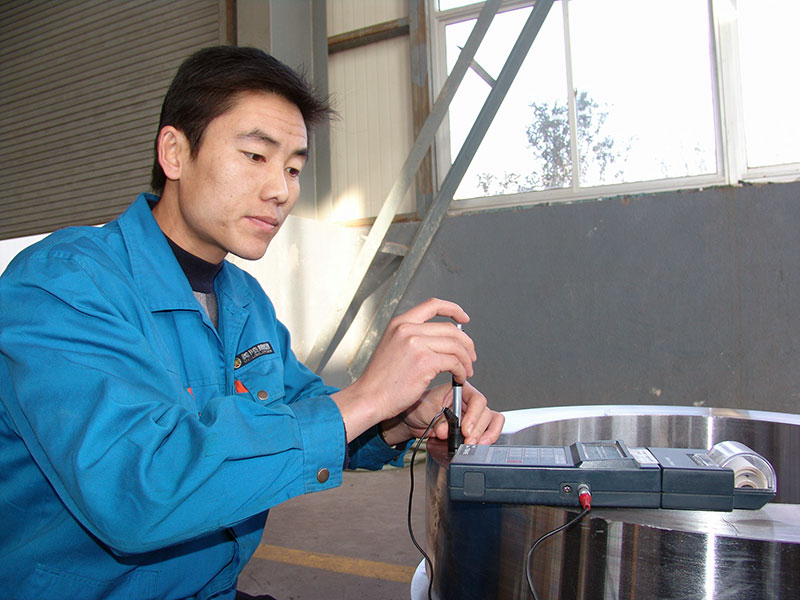

Leeb hardness test

-

Portable spectrometer

-

Digital display universal material testing machine

-

Non-destructive testing

-

Chemistry experiment

-

Low temperature impact test

-

Ultrasonic testing